Six Sigma is a powerful business improvement methodology that combines lean manufacturing and statistical process control to minimize defects, boost quality, and achieve operational excellence. Through certification levels like Yellow Belt to Master Black Belt, professionals learn data analysis skills to make informed decisions. Comprehensive online and institutional training programs enable the implementation of Six Sigma projects, leading to enhanced productivity, cost reduction, and customer satisfaction. In various industries, including manufacturing and healthcare in Valdosta, GA, Six Sigma has proven successful in streamlining processes and improving efficiency through data-driven decision-making.

Discover the transformative power of data-driven decision-making with Six Sigma in Valdosta, GA. This article explores the comprehensive approach of Lean Six Sigma, a methodology that leverages data analysis to optimize processes and drive business excellence. From understanding the core principles of Six Sigma to delving into real-world applications, we uncover why achieving a Six Sigma Black Belt certification is invaluable. Learn about essential tools and techniques used in effective Six Sigma training, and explore successful stories from around Valdosta, showcasing the impact of this powerful methodology.

- Understanding Six Sigma: A Comprehensive Overview for Decision-Making Excellence

- The Role of Data Analysis in Lean Six Sigma Methodology

- Benefits of Achieving Six Sigma Black Belt Certification

- Essential Tools and Techniques for Effective Six Sigma Training

- Real-World Applications: Success Stories from Valdosta, GA

Understanding Six Sigma: A Comprehensive Overview for Decision-Making Excellence

Six Sigma is a powerful methodology designed to enhance business processes and decision-making through data analysis. It focuses on reducing defects and variations, improving quality, and achieving operational excellence. The core principles of Lean Six Sigma combine the lean manufacturing efficiency strategies with statistical process control techniques, ensuring every step in a process is optimized. This approach is particularly beneficial for organizations aiming for consistent, high-quality output and customer satisfaction.

Understanding Six Sigma involves grasping its certification levels, such as Yellow Belt, Green Belt, Black Belt, and Master Black Belt, each with specific roles and responsibilities. The Yellow Belt is an entry point for those interested in basic six sigma concepts, while the Black Belt level delves into advanced data analysis and project leadership. Comprehensive training programs, available online and through professional institutions, equip individuals with the skills to identify process improvements and make data-driven decisions. By implementing Lean Six Sigma principles, businesses can transform their operations, leading to increased productivity, reduced costs, and improved customer experiences.

The Role of Data Analysis in Lean Six Sigma Methodology

In the heart of Lean Six Sigma methodology lies a profound reliance on data analysis as a powerful tool for driving process improvement and efficiency. This approach, often characterized by its rigorous and structured nature, leverages data to uncover insights that may otherwise remain hidden. By implementing six sigma principles, organizations can master data-driven decision-making processes, leading to enhanced productivity, cost reduction, and overall operational excellence. A six sigma black belt, for instance, is an expert in navigating complex datasets to identify variations and defects, enabling them to implement targeted solutions that significantly impact business outcomes.

The integration of six sigma training within organizations ensures that teams are equipped with the necessary skills to interpret data accurately. This involves understanding statistical methods, process mapping, and root cause analysis, all of which are essential components in identifying inefficiencies and implementing effective remedies. What sets Lean Six Sigma apart is its focus on continuous improvement; it encourages a culture where data-driven decisions become the norm, fostering an environment that promotes innovation and adaptability in response to evolving market demands.

Benefits of Achieving Six Sigma Black Belt Certification

Achieving Six Sigma Black Belt certification is a significant milestone for any professional aspiring to excel in data-driven decision-making and process improvement. This prestigious designation equips individuals with advanced skills in the Six Sigma methodology, a powerful lean manufacturing toolset that has been successfully applied across various industries. By delving into the intricacies of this framework, certifies gain a comprehensive understanding of statistical tools, data analysis techniques, and process control methods.

The benefits are multifaceted. First, it enhances career prospects by demonstrating expertise in optimizing business processes, reducing waste, and increasing efficiency. Secondly, Six Sigma Black Belt certification fosters a culture of continuous improvement within organizations, empowering professionals to identify and eliminate defects, ultimately enhancing customer satisfaction and organizational performance. Moreover, the lean six sigma principles learned equip individuals with valuable skills that are transferable across sectors, making them highly sought-after assets in today’s competitive business landscape.

Essential Tools and Techniques for Effective Six Sigma Training

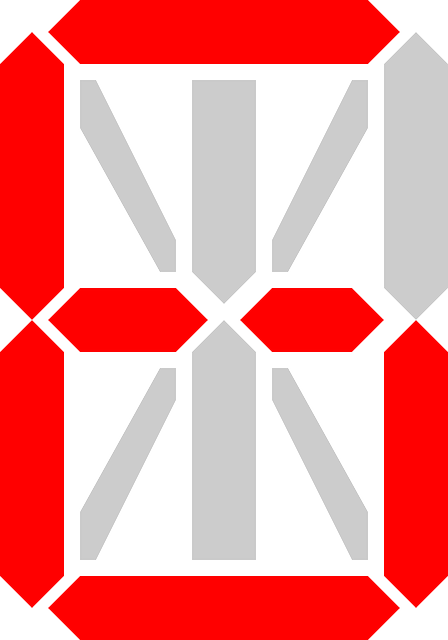

Mastering Six Sigma requires a toolkit of essential tools and techniques that enable data-driven decision-making. At its core, Six Sigma, including Lean Six Sigma, leverages statistical methods to identify and eliminate defects in processes, driving business efficiency and customer satisfaction. For those looking to embark on this journey, understanding the fundamentals is crucial. This includes grasping the concepts of process improvement, root cause analysis, and statistical tools like hypothesis testing and regression analysis. Earning a Six Sigma certification, such as becoming a Six Sigma Black Belt, signifies proficiency in these methods and a commitment to fostering a culture of continuous improvement within organizations.

Effective Six Sigma training goes beyond mere understanding; it empowers individuals to apply these principles practically. Key techniques include data collection and visualization using tools like control charts and Pareto diagrams, which help identify trends and anomalies. Additionally, learning how to design experiments, conduct analysis, and implement solutions based on real-world data is paramount. The Lean Six Sigma methodology, with its structured approach, ensures that every step from defining the problem to measuring success is methodical and focused on delivering tangible results, making it a valuable skill for any professional aiming to excel in data analysis and process optimization.

Real-World Applications: Success Stories from Valdosta, GA

In real-world applications, Six Sigma has proven its worth in various industries within Valdosta, GA. Businesses have successfully adopted lean Six Sigma principles to streamline processes and enhance efficiency. For instance, a local manufacturing plant utilized Six Sigma methodologies to reduce waste and improve product quality, resulting in significant cost savings and increased customer satisfaction. This success story highlights the practical benefits of implementing Six Sigma techniques, enabling organizations to make data-driven decisions and achieve remarkable results.

Another notable example is a healthcare facility that employed a Six Sigma black belt to tackle long patient wait times. Through meticulous data analysis and process optimization, they managed to shorten wait times by over 30%, improving patient experience and operational efficiency. These local success stories serve as a testament to the power of Six Sigma certification and training, empowering professionals with valuable skills to drive positive change in any organization.

Data-driven decision-making has transformed businesses worldwide, and Valdosta, GA, serves as a shining example. By embracing Six Sigma methodologies, specifically the integration of data analysis within Lean Six Sigma principles, organizations can achieve remarkable efficiency gains. The journey towards Six Sigma certification equips professionals with powerful tools like statistical process control, root cause analysis, and defect prevention, fostering a culture of continuous improvement. For those seeking to elevate their career prospects, becoming a Six Sigma Black Belt is a game-changer, offering enhanced problem-solving skills and industry recognition. This conclusion underscores the importance of data analysis in today’s business landscape, encouraging more professionals to explore Six Sigma training for personal growth and organizational success.